Scroll Air Compressor

What is Scroll Compressor?

- This unique concept of scroll-type compressor has been around the corner for more than over a century, but in most recent researches, the scroll compressor became the most common name in the world of compressors. The main reason behind the success of the scroll compressor is its design as well as its intricate and advanced functions.

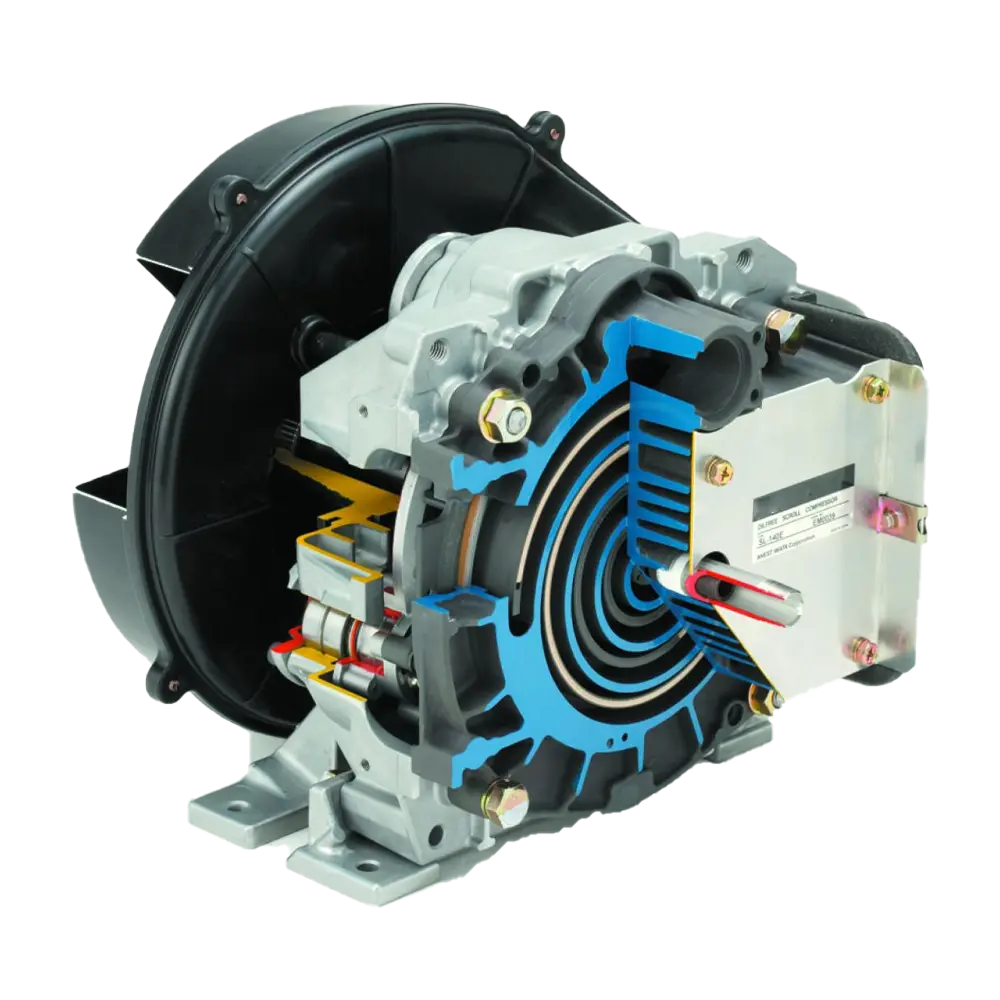

- Two main components of scroll compressors are a stationary scroll and one moving scroll. These two scrolls are identical in shape and appearance. Each of the scrolls is accurately manufactured using modern machining technologies, or we can cast in the shape of a spring which is actually involute in shape.

- The secondary spiralled involute scroll is rotated 180 with respect to the first scroll, and these scrolls mesh with each other. They connected with each other by means of a flat plate and its cover assembly.

Product Description

High-Precision Airend

Scrolls compressors are actually positive-direction displacement devices that work on a principle of internal compression. The Intake air is drawn in a tank, trapped in it, then its volume gets reduced, and this high pressurized air is then discharged through an outlet port.

Efficiency of Scroll Compressors

- The simplified design of scroll compressors makes them much more efficient. That’s the reason why all the leading industries often go for the scroll compressors for designated special systems to meet all the basic requirements needing from a general compressor. Scroll compressors meet the highest volumetric efficiency level, which is 100% because there are no pistons to compress the gas.

- Because of the highest volumetric efficiency, it reduced energy costs in many of the applications of compressors. The presence of pistons typically resulted in re-expansion losses, which can be subtracted by using scroll compressors.

- This high volumetric efficiency is also the by-production of omission of valves because suction valves also do not exist in scroll compressor assembly.

- During the whole process of fluid compression and discharge, centrifugal force keeps up the continued compression and leads to constant leak-free contact between them. This leads to a reduction in heat transfer loss due to the separation of suction fluid and discharge fluid.

Advantages of Scroll compressors

- Lesser moving parts, lesser vibration, and minimum friction also mean these compressors are durable and hence increases the life span of the device helps the user. Fewer moving parts also add one more advantage; it causes less torque variation during operation. This benefit translated to smooth and quiet during the whole operation.

- Simpler design, meaning they usually operate at a very low sound and eliminate the vibration level. In research, it is concluded that the scroll compressors are approximately three to four times quieter than that of the other reciprocating compressor models.

Technical Specification

| Model | Motor Rated Output | Discharge pressure | Discharge Capacity | VOLTAGE /FREQUENCE /PHASE (the voltage can be according to clients requests) | Roating speed | WEIGHT | Diemension(W*D*H) | Noise | ||||||

| KW | HP | bar(MPa) | PSI | L/min | cfm | VOLT | Hz | phase | r/min | KG | mm | dB(A) | ||

| X0.34/8 | 2.2 | 3 | 8(0.8) | 116 | 340 | 12.1 | 220V | 50Hz | single phase | 2800 | 110 | 770*450*780 | 58±3 | |

| JX0.34/8 | 8(0.8) | 116 | 340 | 12.1 | 380V | 50Hz | three phase | 2800 | 110 | 770*450*780 | ||||

| X0.34/10 | 10(1.0) | 145 | 340 | 12.1 | 220V | 50Hz | single phase | 2800 | 110 | 770*450*780 | ||||

| X0.34/10 | 10(1.0) | 145 | 340 | 12.1 | 380V | 50Hz | three phase | 2800 | 110 | 770*450*780 | ||||

| X0.34/12.5 | 4.5 | 6 | 12.5(1.25) | 181 | 340 | 12.1 | 380V | 50Hz | three phase | 2890 | 150 | 830*530*800 | ||

| X0.34/16 | 16(1.6) | 232 | 340 | 12.1 | 380V | 50Hz | three phase | 2890 | 150 | 830*530*800 | ||||

| X0.66/8 | 8(0.8) | 116 | 660 | 23.4 | 380V | 50Hz | three phase | 2890 | 150 | 830*530*800 | 63±3 | |||

| X0.66/10 | 10(1.0) | 145 | 660 | 23.4 | 380V | 50Hz | three phase | 2890 | 150 | 830*530*800 | ||||

| X0.66/12.5 | 7.5 | 10 | 12.5(1.25) | 181 | 660 | 23.4 | 380V | 50Hz | three phase | 2900 | 195 | 950*550*830 | ||

| X0.66/16 | 16(1.6) | 232 | 660 | 23.4 | 380V | 50Hz | three phase | 2900 | 195 | 950*550*830 | ||||

| X1.15/8 | 8(0.8) | 116 | 1150 | 40.7 | 380V | 50Hz | three phase | 2900 | 195 | 950*550*830 | 68±3 | |||

| X1.15/10 | 10(1.0) | 145 | 1150 | 40.7 | 380V | 50Hz | three phase | 2900 | 195 | 950*550*830 | ||||

| X1.15/12.5 | 11 | 15 | 12.5(1.25) | 181 | 1150 | 40.7 | 380V | 50Hz | three phase | 2920 | 230 | 1030*600*900 | ||

| X1.15/16 | 16(1.6) | 232 | 1150 | 40.7 | 380V | 50Hz | three phase | 2920 | 230 | 1030*600*900 | ||||

| Environmental temperature | -5~45 | |||||||||||||

| Discharge temperature | Ambient temperature +50℃ | |||||||||||||

| Oil Carryover of discharged air | ≤3 | |||||||||||||

| Cooling Mode | Air cooling | |||||||||||||

| Drive Mode | Coaxial connecting | |||||||||||||